Price: $29.95 - $22.32

(as of May 08, 2024 06:13:37 UTC – Details)

From the Publisher

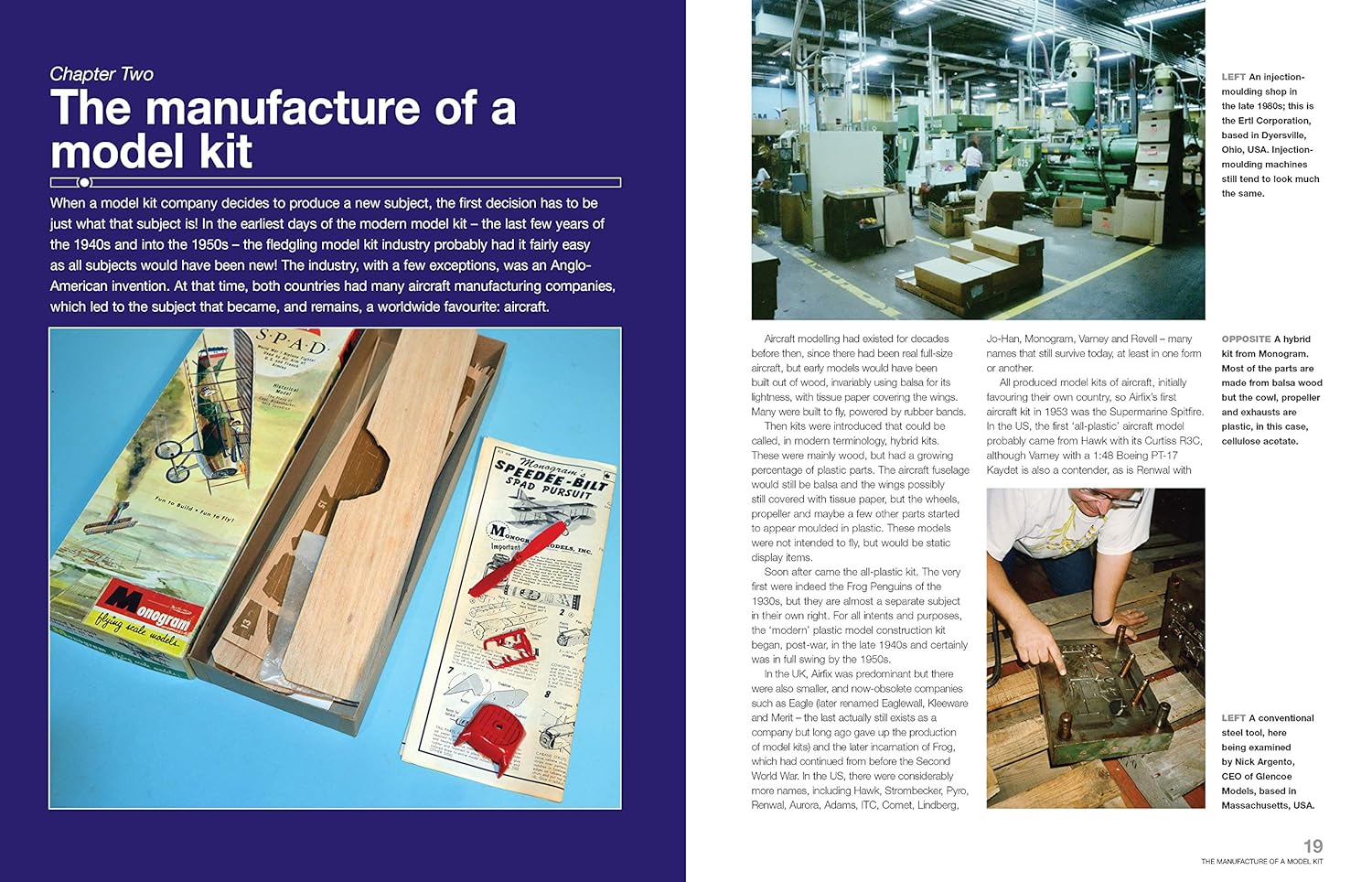

The manufacture of a model kit

When a model kit company decides to produce a new subject, the first decision has to be just what that subject is! In the earliest days of the modern model kit – the last few years of the 1940s and into the 1950s – the fledgling model kit industry probably had it fairly easy as all subjects would have been new! The industry, with a few exceptions, was an Anglo-American invention. At that time, both countries had many aircraft manufacturing companies, which led to the subject that became, and remains, a worldwide favourite: aircraft.

Drills

Holes may have to be drilled, and here you have the option of hand-operated drills – usually called a pin-vice (or vise), or an electric drill. Both have their uses. The pin-vice is invariably more precise, especially as it has very small drill bits for drilling tiny holes. However electric drill sets – besides being faster and time-saving when multiple holes have to be drilled – can also be fitted with other tools. These include sanding discs, cutting discs and polishers.

The electric variety can be mains or low voltage, and most will come with a speed control, as most of the time it will be vital to control the speed of the operation. Electric drill controllers often have companion tools that can plug in to the same transformer, such as a small jigsaw, which is invaluable for many other tasks.

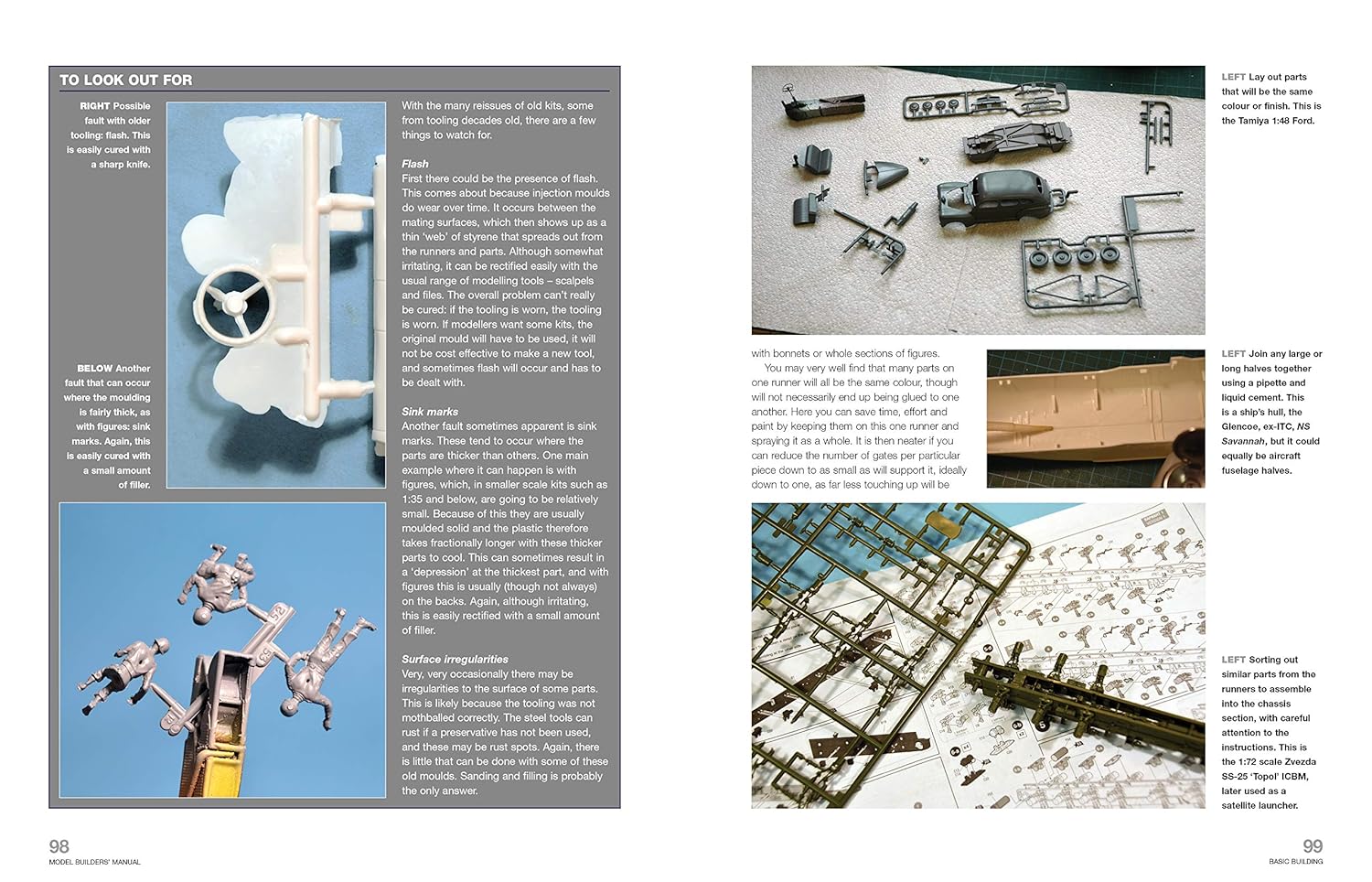

TO LOOK OUT FOR

Flash

First there could be the presence of flash. This comes about because injection moulds do wear over time. It occurs between the mating surfaces, which then shows up as a thin ‘web’ of styrene that spreads out from the runners and parts. Although somewhat irritating, it can be rectified easily with the usual range of modelling tools – scalpels and files. The overall problem can’t really be cured: if the tooling is worn, the tooling is worn. If modellers want some kits, the original mould will have to be used, it will not be cost effective to make a new tool, and sometimes flash will occur and has to be dealt with.

Sink marks

Another fault sometimes apparent is sink marks. These tend to occur where the parts are thicker than others. One main example where it can happen is with figures, which, in smaller scale kits such as 1:35 and below, are going to be relatively small. Because of this they are usually moulded solid and the plastic therefore takes fractionally longer with these thicker parts to cool.

Surface irregularities

Very, very occasionally there may be irregularities to the surface of some parts. This is likely because the tooling was not mothballed correctly. The steel tools can rust if a preservative has not been used, and these may be rust spots. Again, there is little that can be done with some of these old moulds. Sanding and filling is probably the only answer.

Publisher : Haynes Publishing UK (July 23, 2019)

Language : English

Hardcover : 188 pages

ISBN-10 : 1785215558

ISBN-13 : 978-1785215551

Item Weight : 1.6 pounds

Dimensions : 8 x 0.5 x 11 inches

Reviews

There are no reviews yet.